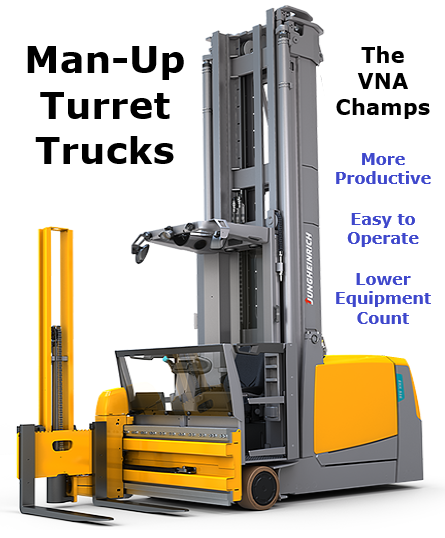

Man-Up Turret-Trucks, are class 2 trucks known to be a “very narrow aisle” option in the intra-logistics or material handling spaces.

Of all of the traditional type of lift trucks the Man-Up Turret Truck is likely the best-kept secret in operation today, and possibly the most underestimated.

Price point, often being a factor in deciding between a turret truck, and an articulating counterbalance truck like the Bendi from Landoll. There are several reasons and factors that contribute to bringing one to the decision of Bendi or Man-Up Turret-Trucks, and also which setup to go with, and this article is to be an aid to navigate those options and obstacles effectively.

To analyze the benefits of this type of truck, and how those factors offset their cost and maximize the operations they are used in, and keep it short, 3 of the following factors will be expounded upon;

Easy to Operate

Interchangeable Functions

Consistent Aisle Width.

Easy to Operate

The ease of operation for a Terret truck is in the fact that it can be used on a “wire”, meaning that it is guided electronically to stay straight in the aisle. The operator of a MUTT, in a properly designed configuration, will do most of their maneuvering when changing aisles. If trained properly, there will be virtually no encounters with the legs and bases of the racks.

The controls for the MUTT are typically a steering wheel and two control handles with paddle buttons for the travel and lift features. Most trucks of this type are made by leading manufacturers and are fully AC-powered by the battery which gives the operators a high degree of control over the movements of the truck. If the Jungheinrich version is anything like all the other trucks in its family, then its smoothness will be rivaled only by its efficiency.

These types of trucks are longer than most electric narrow aisle trucks, but it takes just a few minutes for an unfamiliar operator to get acquainted with it. One thing that gives them an advantage over a reach truck is that they do not turn in the aisles, and that takes a step out of training. It is also significantly better in the area of risk mitigation since the operators of MUTTs cannot develop the habit of “swooping” as is the case with reach trucks and other trucks that stack and tier at higher levels. This is also an advantage over the Articulating Counter Balanced Trucks since they also offer the opportunity to swoop loads, which is basically turning and lifting or lowering at the same time.

Interchangeable Functions

MUTTs really are a happy mix of different breeds and have taken on the better qualities of each. In this case, the Turret Truck can replace the reach truck and order selectors. Most of them come with the option to use a seat and/or fall protection for standing up to grab small items and place them on the pallet. All of my encounters with the Turret Trucks make it very difficult for the operator to rest their free hand on the side gate when lifting and lowering, which is a bad habit for most operators that I’ve worked with on the Order Pickers (OPs).

@JungheinrichAmerica on YouTube

Another unrecognized hazard elimination feature on MUTTs is that the pallet rests on the forks in a way that doesn’t require a pallet clamp. Although OPs have “pallet clamps”, and although they work great, the operator of a MUTT would have to work hard to allow for the potential of the pallet slipping off and them falling through and being injured.

Generally, the MUTTs are a mixture of reach trucks and Order Pickers and with careful consideration can eliminate the need for both, and the benefit of fewer classes of trucks in any operation cannot be overstated. Fewer types of forklifts in an operation make it much easier to train operators effectively for starters, and then gives supervisors less to look at in regards to proper operation. Simpler is safer, and the more classes of trucks that need to be covered the more expensive and time-consuming training will be.

Operators who operate multiple types of trucks will inevitably be transitioning from truck to truck. This transitioning will take time, and there will be shortcuts in the process to shorten the transitions. Although, on a normal day, the shortcuts will seem unnecessary, the habits formed in the rush will be the ones that stick. Not only will the shortcuts like not wearing seatbelts and swooping stick but the operating principles of one lift will be carried over to another, and this can also present a variety of stability management and other hazardous issues that can be eliminated with fewer trucks.

Consistent Aisle Width

When designing a warehouse, like anything else, the fewer the variables the more efficient and effective the design process will be. As stated before, simpler is safer. If a warehouse has to make aisles for reach trucks, which do not go past 4.500 lbs. capacity, and OPs, then they will have to calculate precisely how much of the aisles they will use. If the entire warehouse is designed for reach trucks, then efficiency diminishes with every aisle that is used.. And no matter which, there is still the need to load trucks, which MUTTs cannot do, but neither can reach trucks or order pickers.

Therefore, if there are no OPs, no reach trucks, and just MUTTs, then all aisles can be the same. This will enable for the same operator to pick, pull, and restock from the same truck. And if there is an area where loads exceed 4,500lbs then that can usually be handled with the same truck that loads from the docks.

Warehouse management is vastly easier with fewer classes and consistent aisle widths, regardless of whether or not you have Man-Up Turret Trucks. But the MUTTs are the way to go to fast track to that level of streamlined operation.

So, with that information you can now see why the Man-Up Turret-Truck may be the way to go for the next project whether selling, buying, or designing.

Thank you for reading, and if you have questions, click here for answers.

By Dustin Link